Reference: ZAKETHADICE_50-CM

Brand: DIVERS DIRECT

LP inflator hose standard, Divers Direct

Medium pressure hose for inflator or dry suit, optionally in lengths of 0.20 - 0.80 m.

Reference: ZAKETHADICE_50-CM

Brand: DIVERS DIRECT

Medium pressure hose for inflator or dry suit, optionally in lengths of 0.20 - 0.80 m.

Reference: STRAP

Brand: SOPRASSUB

Strap for tank fastening or weight belt, price per meter.

Reference: LEPIDLODM

Brand: Divemarine

Neoprene glue black 50g, Divemarine Sale

Reference: ZAKETHADICEFLEX_100-CM

Brand: DIVERS DIRECT

Flexible, medium pressure hose for inflator or dry suit with double outer braid, optionally in lengths of 0.20 - 1.00 m.

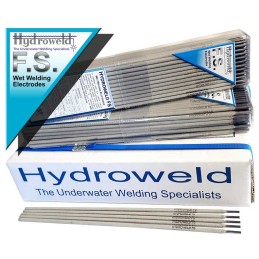

Hydroweld FS™ are the standard electrodes for wet welding where high quality underwater welding is required. These unique electrodes are specifically designed to produce high quality welds underwater, in fresh or salt/sea water, in all positions and on a variety of carbon steels and at different water depths. Their excellent user-friendly properties and wet welding characteristics have made them the choice of professional welders worldwide.

Hydroweld FS™ are the result of extensive research and development of flux formulations, filler metals and additive coatings. This research and subsequent development has been primarily focused on solving the metallurgical, weldability and practical problems commonly associated with underwater welding, enabling significant improvements in wet weld quality that are unattainable with other currently available wet welding electrodes.

Hydroweld FS™ has earned an unrivalled and proven track record in this area, particularly in wet welding of structures in all sectors of industry, including offshore oil and gas, marine/commercial shipping, civil/marine/naval and nuclear. Due to their reliability and performance, they are widely regarded as the industry standard for wet welding.

Hydroweld FS™ can meet or exceed the weld quality requirements of AWS D3.6 for underwater welding, the "Class A" criterion for all weld positions on pipe and plate, for both fillet and butt welds, as confirmed by internationally recognized IACS (International Association of Classification Societies) members such as Lloyds Register (LR), American Bureau of Shipping (ABS), Det Norske Veritas (DNV) / Germanisher Lloyd (GL), Bureau Veritas (BV) and Rina.

Hydroweld FS™ wet welds are regularly subjected to unrivalled, intensive testing and research programmes by independent organisations such as welding institutes, universities, military/naval organisations, commercial diving contractors and other respected organisations worldwide.

Hydroweld FS™ are currently the only wet welding electrodes approved by the UK Ministry of Defence (MoD) for permanent and/or temporary repair of naval ships and submarines and included in the NATO (NCAGE) KA125 codification system, and have been approved for inclusion following intensive comparative testing with a range of other commercially available wet welding electrodes by MoD and The Welding Institute (TWI) and have been subjected to extensive non-destructive and destructive testing.

Hydroweld FS™ electrodes are currently available in 3.2mm x 350mm in boxes of 90 electrodes or 4mm x 350mm in boxes of 60 electrodes and/or cartons of 5. We routinely stock over 200,000 electrodes which can be shipped on the day of order in a manner to suit the customer's requirements i.e. next day, 2 to 3 days etc.

Reference: BR20

Brand: Broco

Reference: 525-400

Brand: Kirby Morgan

Reference: TA2238

Brand: Broco

Reference: BR22PLUS

Brand: Broco

Reference: UWSS1

Brand: Broco

Reference: EXODUSW4

Brand: EXODUS

Reference: NAUTICACUT

Brand: voestalpine Böhler Welding

Reference: 525-411

Brand: Kirby Morgan

Reference: UW381850

Brand: Broco

Reference: 525-403

Brand: Kirby Morgan

Reference: EXODUSD_BEZ-IZOLANTU

Brand: EXODUS

check_circle

check_circle